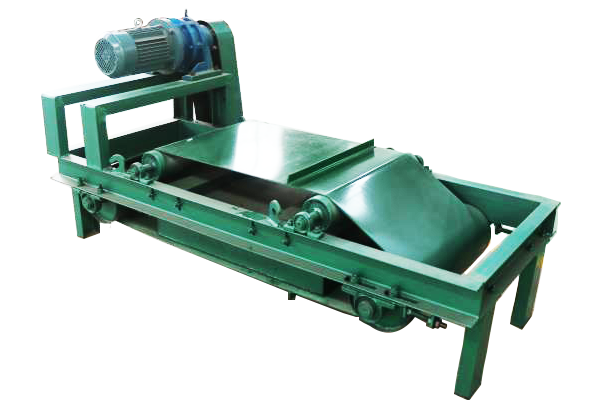

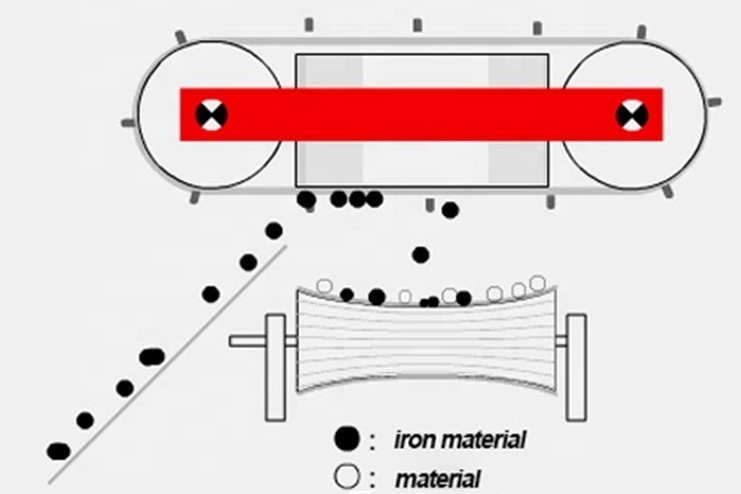

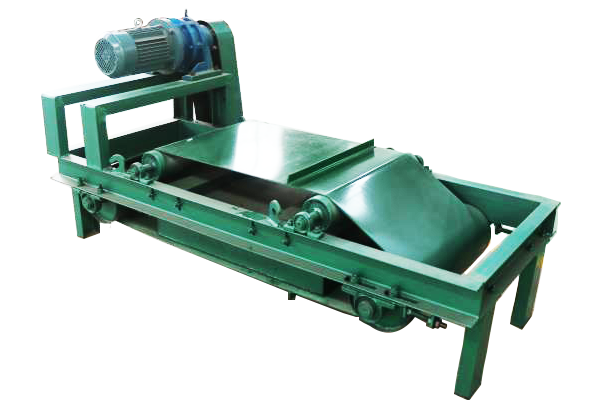

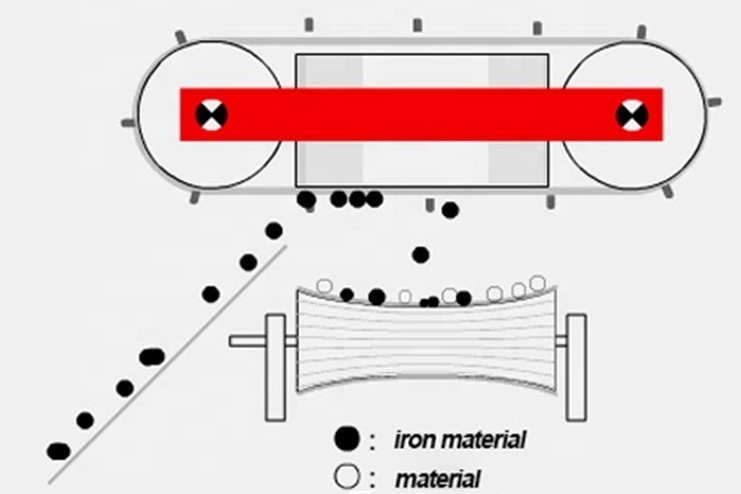

Permanent magnetic iron separator for iron removing is used to eliminate the ferromagnetic material weighing from 0.1kg to 35kg, to ensure the safe operation of transmission system of the crusher, grinding machine and other mechanical equipment.

Permanent magnetic iron separator for iron removing is suitable for all industries to remove iron, can realize continuous suction, and discard iron.

After the tray crusher has finished crushing the tray containing iron nails, the material containing iron can be adsorbed and separated by permanent magnetic iron separator for iron removing, and then transferred out through the conveyor belt.

Permanent magnetic iron separator for iron removing is made up with permanent magnetic chip of robust performance, iron-discharging belt, reducer, frame and roller etc. and can match with all kinds of conveyors.

Permanent magnetic iron separator for iron removing adopts the computerized simulating and makes it still work in the harsh environment for a long period.

Permanent magnetic iron separator for iron removing is widely used in metallurgy, mines, coal preparation plants, power plants, ceramics, glass, cement, building materials, chemicals, food and feed processing industries. In the emerging waste treatment industry, iron eliminators are also needed to recover the waste of iron and steel.Iron remover has been used in large iron and steel enterprises, as well as metal mines, power plants, light industry, refractories and other industries, and has played a huge role.

|

Mode |

Usable

belt

width

(mm) |

Standard

erection

height

(mm) |

Mass

(kg) |

Overall

dimension

(mm) |

Unload

trigger

spec. |

Driving

motor

power

(kw) |

|

|

|

|

|

A |

B |

C |

D |

E |

|

|

|

HR-6 |

650 |

200 |

880 |

2100 |

950 |

420 |

888 |

900 |

2.7 |

2.2 |

|

HR -8 |

800 |

250 |

1790 |

2050 |

1105 |

650 |

1038 |

1280 |

2.7 |

2.2 |

|

HR -10 |

1000 |

300 |

3060 |

2240 |

1310 |

785 |

1238 |

1370 |

3.3 |

3.0 |

|

HR -12 |

1200 |

350 |

4680 |

2440 |

1585 |

875 |

1512 |

1350 |

3.3 |

4 |

|

HR -14 |

1400 |

400 |

6600 |

2700 |

1765 |

970 |

1690 |

1550 |

4.1 |

4 |

|

HR -16 |

1600 |

450 |

8060 |

2900 |

1965 |

1050 |

1890 |

1750 |

4.2 |

5.5 |

|

HR -18 |

1800 |

500 |

10250 |

3150 |

2230 |

1150 |

2150 |

1960 |

6.8 |

5.5 |

|

HR -20 |

2000 |

500 |

12850 |

3380 |

2460 |

1280 |

2380 |

2170 |

16 |

7.5 |