Continuous Carbonization Furnace

Continuous carbonization furnace makes charcoal from wood, sawdust, bamboo, coconut shell, rice husk, stalk, agro wastes and many other biomass materials. How to Make Charcoal from Biomass Materials?

Learn More

The charcoal can be turned to charcoal briquettes with different shapes by charcoal briquette machines.

Related Product :

Charcoal Briquette Machine

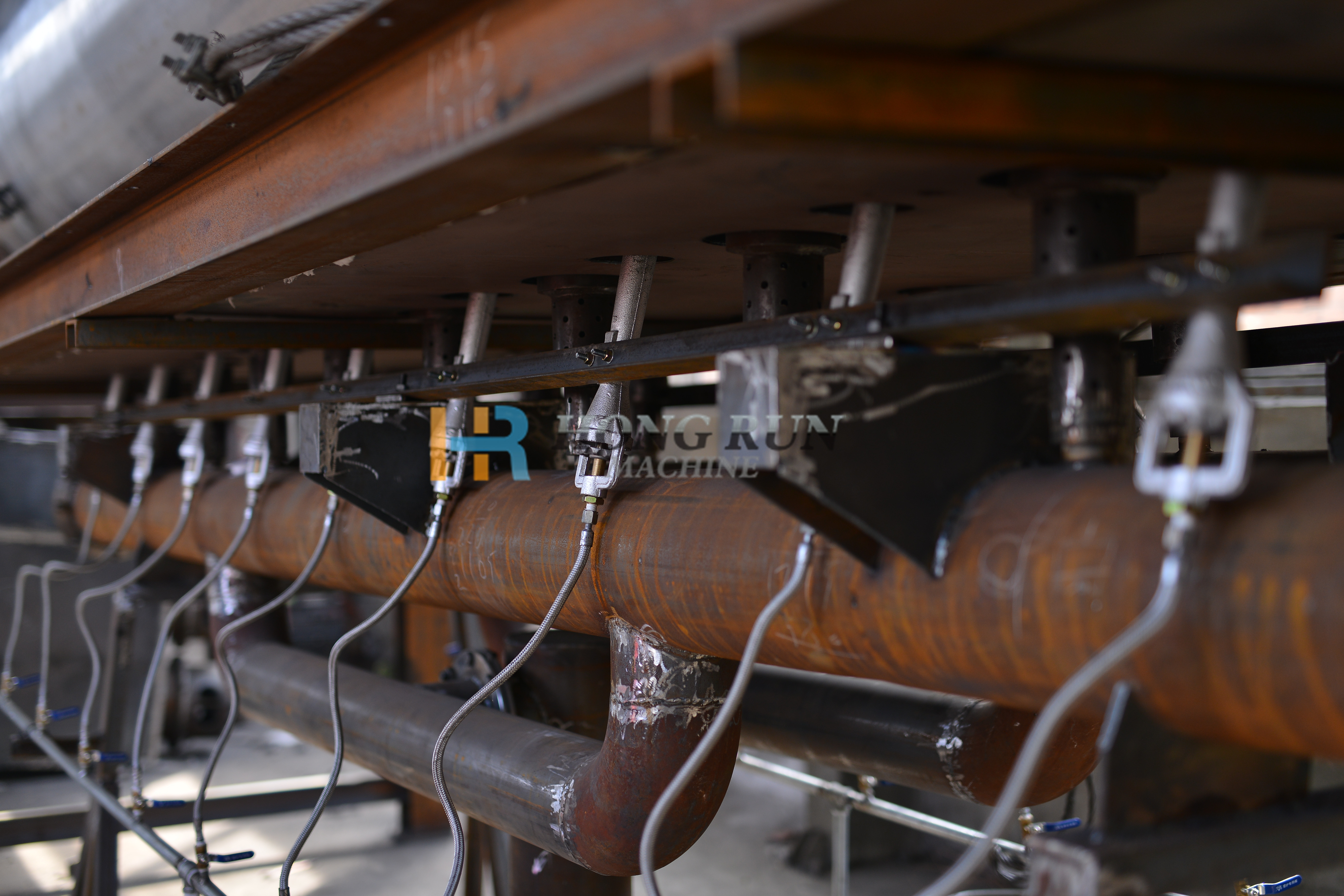

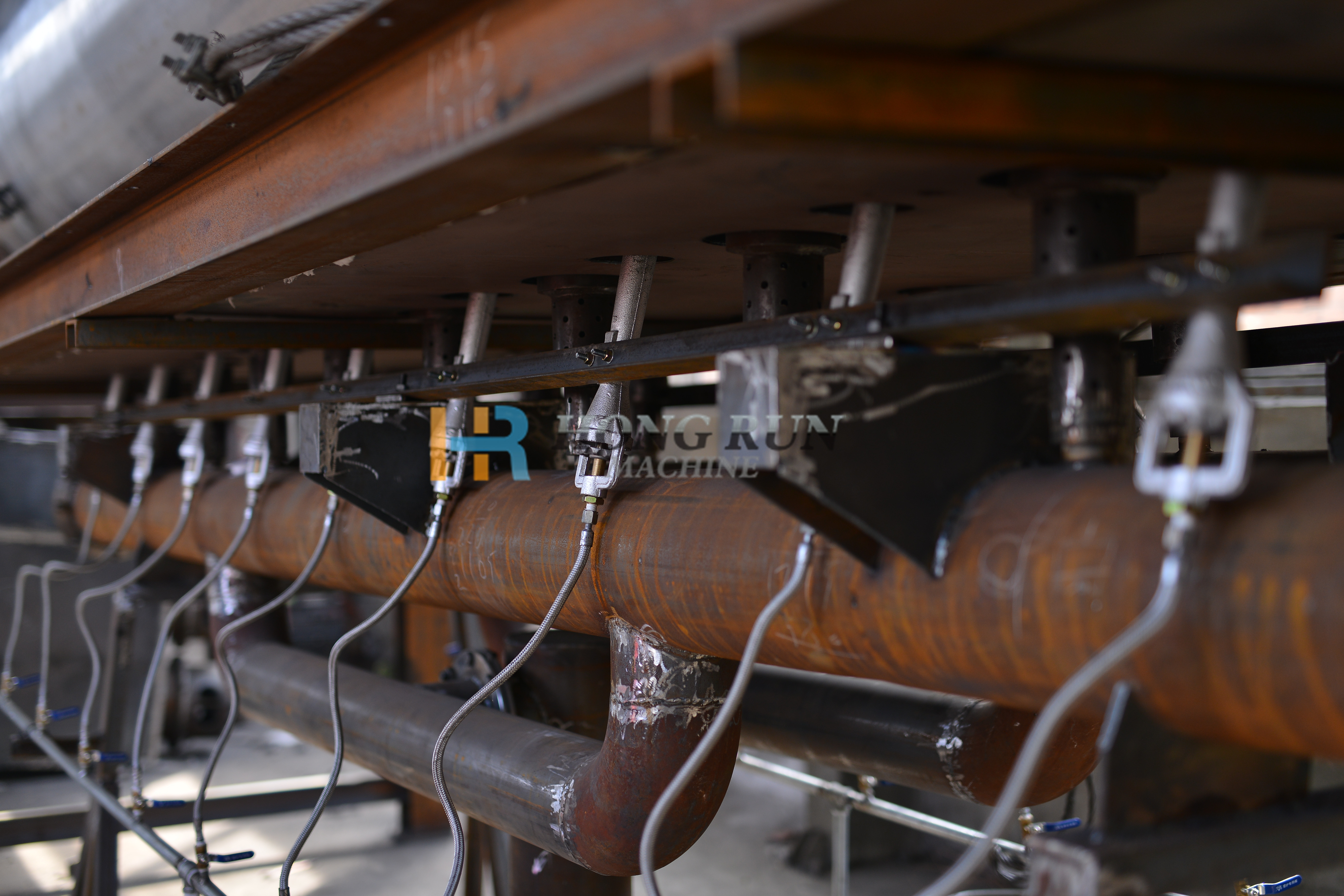

Environmental protection continuous carbonization furnace is still the use of gasification carbonization principle, the use of advanced smoke-free environmentally friendly carbonization process: the entire equipment from the gasification system (gasifier, spray tower, dust collector), purification system Leach, oil and water separator, filter), carbonization system (carbonized host, screw feeder, screw feeder, cooling machine, conveyor, finished cooling warehouse), control system (control cabinet), the entire carbonization Process for automated production, automated operation.

Hongrun energy-saving environmental protection continuous carbonization machine has two significant advantages: First, the host capacity, high carbonation rate, strong production capacity, per hour carbonized rice husk about 1 ton; Second, low cost, cost Low practicality, to meet the initial entrepreneurial investment benefits of small objective requirements.

Gongyi Hongrun energy-saving environment-friendly continuous carbonization machine is a reasonable use of materials in the carbonization process, the production of carbon monoxide, methane, oxygen and other combustible gas recovery, purification, recycling combustion of advanced technology. Both to solve the ordinary carbonization furnace in the carbonization project generated by the smoke on the environment pollution problems, but also to solve the equipment required for thermal problems, fully self-sufficiency, improve the continuity of equipment, economy, environmental protection, energy saving Nature, and efficiency, make full use of agricultural and forestry residues, make it waste into treasure, reduce the contradiction between supply and demand of forestry resources, and make more contributions to the green environment.

The datas:

|

Product |

Model |

Speed |

Capacity |

Size m |

Power kW |

Continuous

Carbonization Furnace |

1000 |

3-5/Min |

400-600kg/h |

1.4×2.7×9.6 |

4 |

|

1200 |

800-1200kg/h |

1.7×3.1×12 |

5.5 |

|

1500 |

1500-2000kg/h |

2×3.5×12 |

7.5 |

Below photo is

the upgraded version of double-layer continuous carbonization furnace. The upgraded version of double-layer continuous carbonization furnace can also be used to recycle and process electronic waste& scrap metals, such as used beverage cans (UBC) paint removing. Click the below photo for more information.

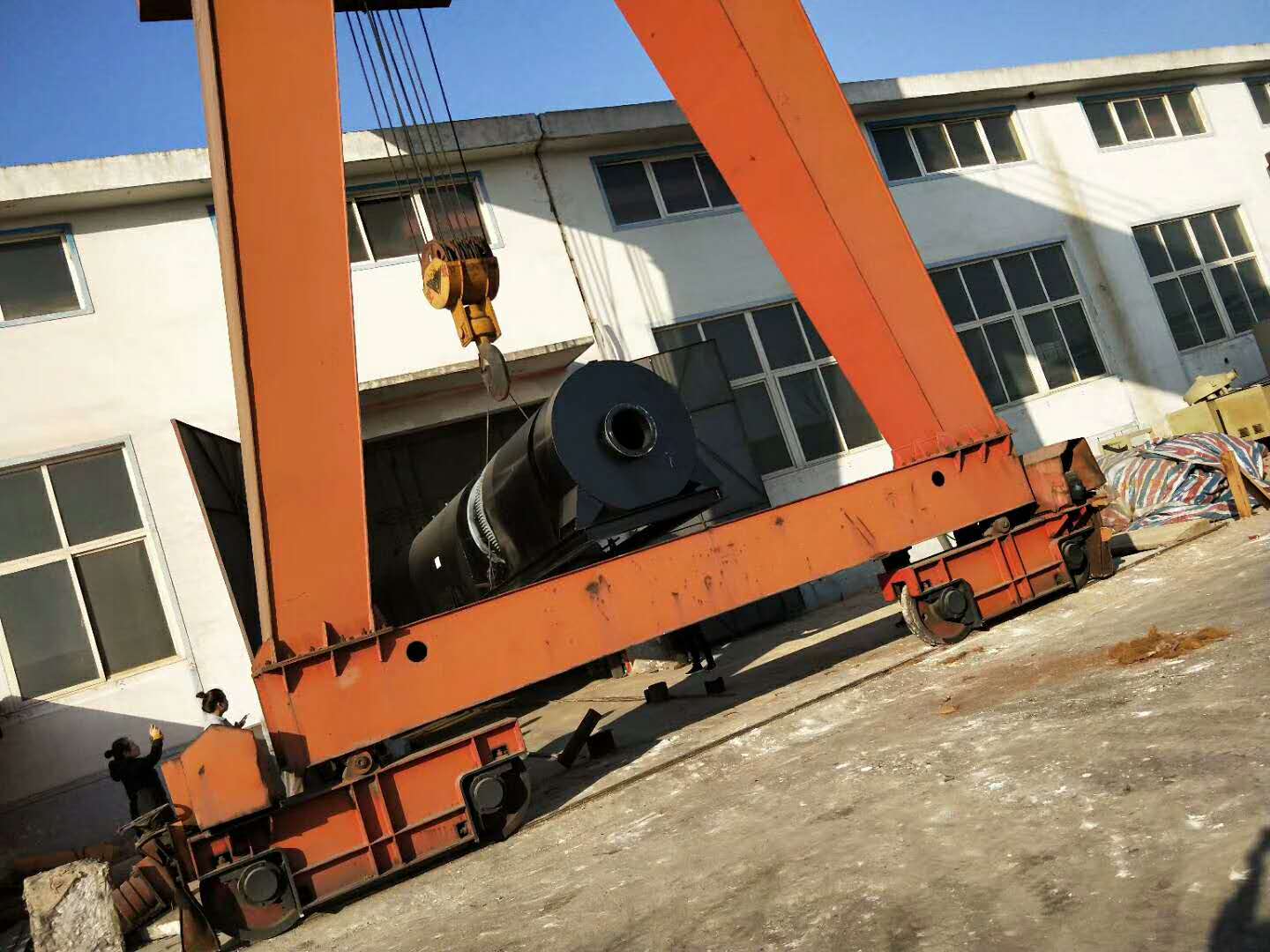

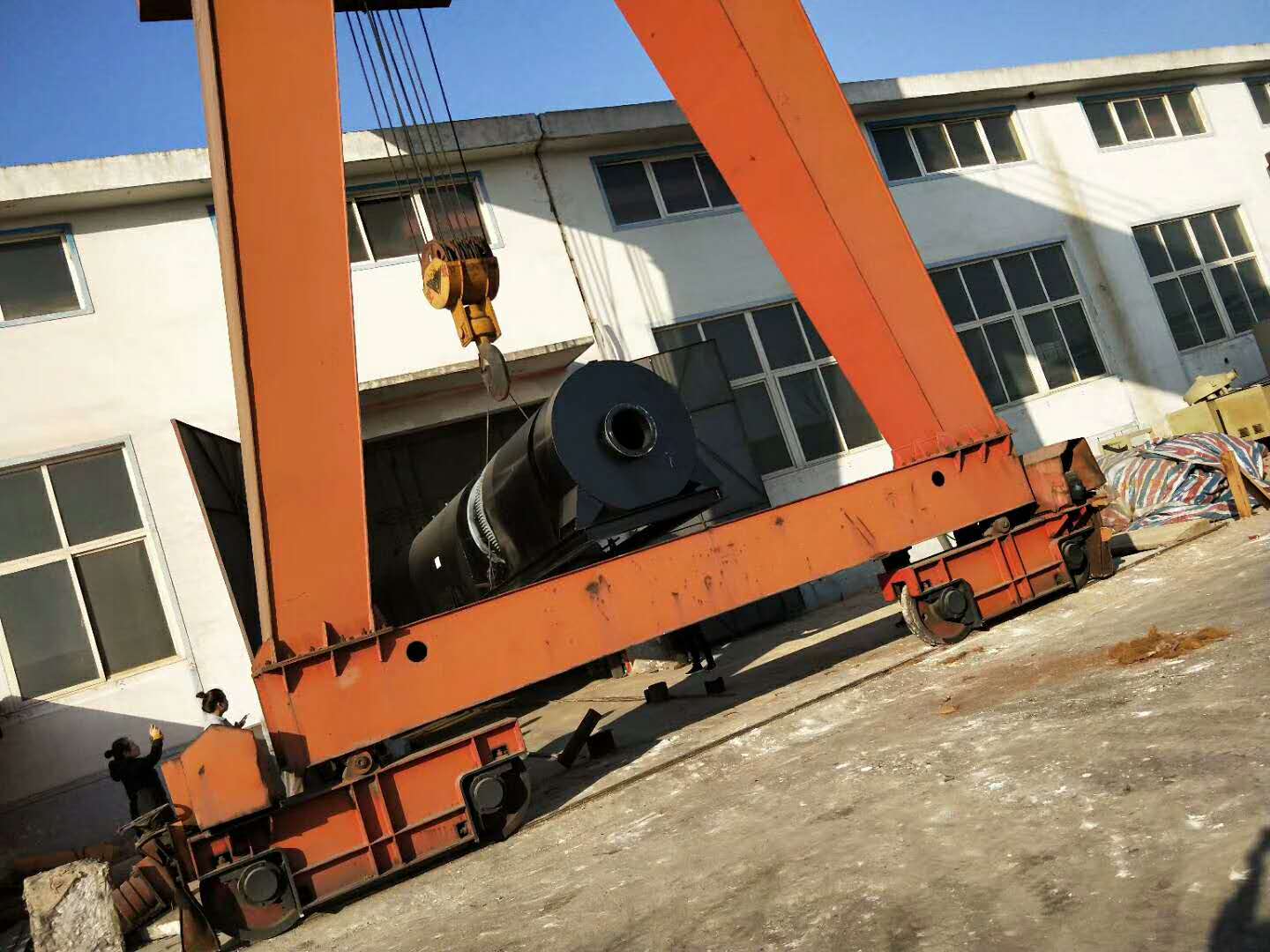

Continuous carbonization furnace exported to UK. Photos from delivery site:

South African Customer Production Site

Gongyi Hongrun Machinery Equipment Co., Ltd. mainly produces charcoal making production line machinery and equipment, including wood crusher, carbonization furnaces, drying equipment, charcoal briquette machines, etc, which can successive deal with material until finishing molding charcoal products. The raw materials of finishing molding charcoal products come from wood, coconut shell, bamboo, straw, grain shell and so on.