Welcome to HONGRUN Machinery

Charcoal Ball Machine

Introduction to Charcoal Ball Machine:

The charcoal ball machine is mainly used to press the charcoal dust that is hard to mold, which is characterized by big molding pressure, adjustable host rpm with a screw feed device. The charcoal ball pressing machine can be used for charcoal powder molding, coal molding; powder molding; gypsum molding; coke powder molding and scrap iron molding.

Function of Hongrun Ball Pressing Machine:

Hongrun charcoal ball press machine can be used to deal with coal powder, iron powder, coke, aluminum powder, scrap iron, iron oxide skin, carbon dust, charcoal powder, mining slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze and other materials. This product can be find in many industries like refractory, power plants, metallurgy, chemical industry, energy, transport, heating, etc. Charcoal balls made by Hongrun ball machine has the advantages of energy saving, easy transport, greatly improving waste utilization.

Working Principle of Hongrun Charcoal Ball Machine:

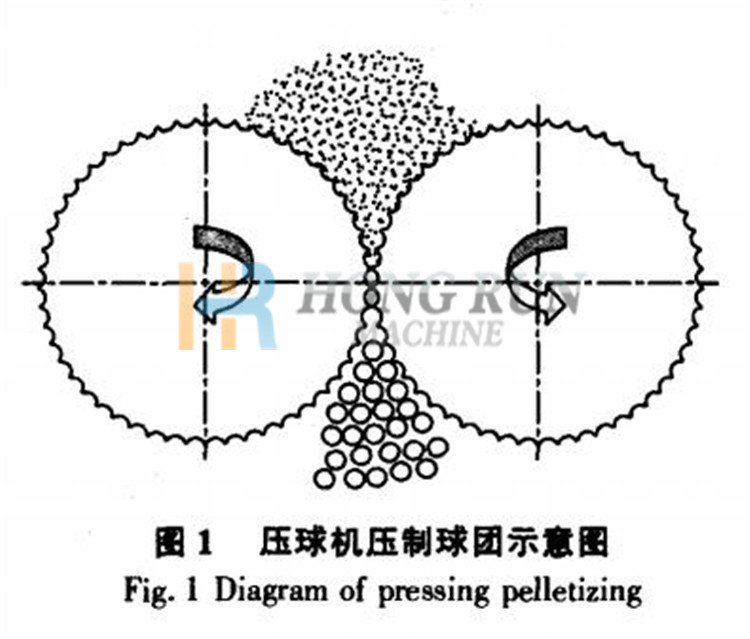

From the storage silo, the material is fed into the molding machine hopper evenly by the quantitative device. Then the regulation board on the hopper make the materal evenly enter into the middle of the roller; the reverse operating roller compress the material and the forming pressure increases gradually, at the centerline of the roll the forming pressure reaches its maximum value, once the material through the line, the molding pressure rapidly decrease so that the material forms into ball shape and smoothly discharge the ball.

The charcoal balls/briquettes made by the charcoal ball machine can be used as BBQ charcoal fuel. The following picture shows the BBQ charcoal briquettes. Click to See BBQ Charcoal Machine.

Technical Parameters of the Charcoal Balls Machine:

Hongrun series machine list: wood crusher machine| straw crusher machine cost| wood chip crusher| wood powder machine crusher mill pulverizer| hammer mill crusher| charcoal pulverizer crusher| chicken manure drying machines| grain dryer machine| rotary dryer installation| tumble dryer air pipe| air pipe dryer in China| sawdust dryer for sale| mineral rotary dryer| box type dryer machine| charcoal rod making machine| charcoal ball making machine| charcoal tablet press machine| charcoal briquette extruder machine| hoisting type carbonization furnace| palm fiber rotary carbonization furnace| coconut shell charcoal carbonization Furnace| biomass sawdust dryer| BBQ charcoal equipment| environmental protection carbonization furnace| hookah charcoal making machine| charcoal machine equipments| mechanism charcoal machines| charcoal machines price| straw rod making machine| charcoal powder tablet press machine

Make Use of Ball Pressing Machine to Make Right Ball with No Risk

A special welcome to Hongrun charcoal Machines Company and it filled with a number of the machinery for molding and furnace to major industries. Hope you can go with our company to obtain brand and quality product at all time without meeting any risk. If you are searching for brand charcoal ball pressing machines, our company strand at first and top of significant people, this kind of tools are made use to hit and press their dust. it is hard to mold because it has characterized by considerable molding pressure and also have adjustable host rpm with screw device — it machine used for powder molding, gypsum, coke powders and finely scrap iron molding. Therefore the chemical industries can feel free to hire and get the best and effective solution and support to order suitable ball pressing machine with the presence of updated features to handle the wide task easily. Even you can save a lot of time and cost.

The Function Of The Ball Pressing Machine

At first, user need not fed material into the machine hopper with the help of quantitative material, and hopper makes all material into the center part of the roller and then reverse operation roller get compress the content which is inside the hopper. Once the pressure reaches a high level, then the material start t via the line and decreases, so it forms into the ball shape and finally discharges the ball. Hope you can try out with ball pressing machine and get significant benefits and bring even shape at all time. On the other hand it same lot of time and money on using this ball pressing machine Our company expert in having a wood crusher, sawdust dryer carbonization furnace and also other successive deal with different material until the molding products. Each product can take for end number of process form world top brand so you can get the call and get advice from experts to fix some common problem.